You may learn about Adam Smith’s “Division of labor” or Henry Fayol’s “Division of Work”. By a commonsense both propagate same sort of process within an organization. Both depict enriching skill and specialization in a functional area of work. In this process, the whole organization is divided into a number of functional departments and the people employed in those departments practice same type of activities over the time and thus acquire a sort of specialization. Because of their skill and experience in a specific area of work, they need less time and cost to complete the work with a standard quality. An efficient co-ordination among the departments and control over the whole process ensure the expected organizational output.

Now in the 21st century with the boom of information technology and globalization the concept of specialization is going to be practiced in a big picture of organization. Achieving cost-efficiency and increasing customer responsiveness by leveraging information technology is getting importance as a competitive advantage among the companies. Now the managers are trying to find out the area the company is doing best, to find out the core competencies? Now question is arising over the mind of the managers that.

Is it possible to minimize cost or maximize services by focusing on core competencies and leaving other activities to outsource from best available sources?

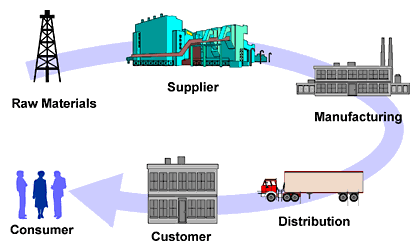

If the answer is positive then the firms can go for an integration policy within its supply chain. The integration of core processes can extend across the organizational boundary through improved communication, partnerships, alliances and cooperation. It also includes the application of new technologies to improve information flows and coordinate the flow of physical goods between trading partners.

The cooperative model, by way of contrast, focuses on the sharing of information (and in some cases assets) between organizations, recognizing areas of common interest and mutual competitive advantage. The requirement for open communication, trust and recognition of the interdependence of “individual” elements of the supply chain as technology implementations bridge company boundaries has thrown further emphasis on the importance of such cooperative strategies. (Stuart, 1997; Dyer et al., 1998)

For example, United Parcel Service (UPS) stocks Nike shoes and warm-ups at its Louisville warehouse and processes orders hourly. All related communication and financial administration are handled by a UPS call-center. Thus Nike has effectively outsourced basic logistics and related value-added services to UPS.(Kelly Barron, 2000)

But implementation of such type of integration is becoming critical facing some challenges. Integration requires parallel information infrastructure. Without same level of sophistication within the business process the opportunity of information technology can’t be leveraged. Interdependence is acute here and a little damage in any channel activity can cause damages in whole supply chain. Above all if the channel members can’t create win-win situation integration will never be possible.